Brief

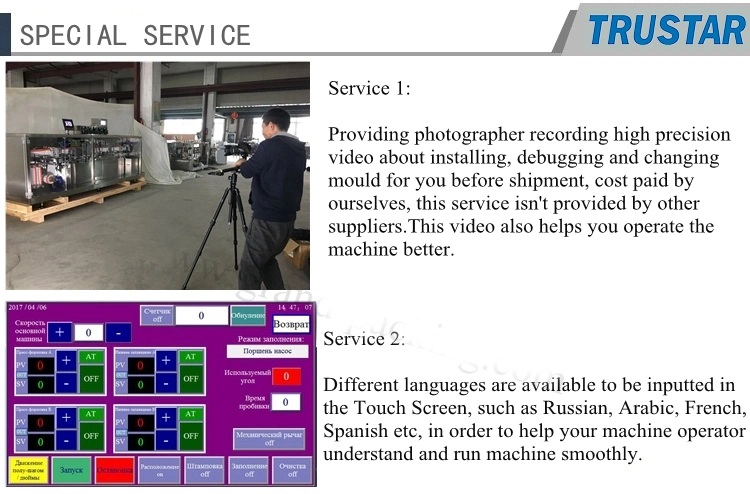

This model is an intermittent motion and hole plate type filling full automatic capsule filling equipment. It adopt optimization design for meeting the characteristics of Chinese medicine and the requirement of GMP, it has the characteristics of compact mechanism, small volume, lower noise, precision filling dosage, multi-function, stably running etc. It can finish the following motion at the same time: capsule feeding, capsule separating, powder filling, capsule rejecting, capsule locking, finished capsule discharge and die hole cleaning etc. It is the most ideal hard capsule filling equipment for pharmaceutical and health food industry.

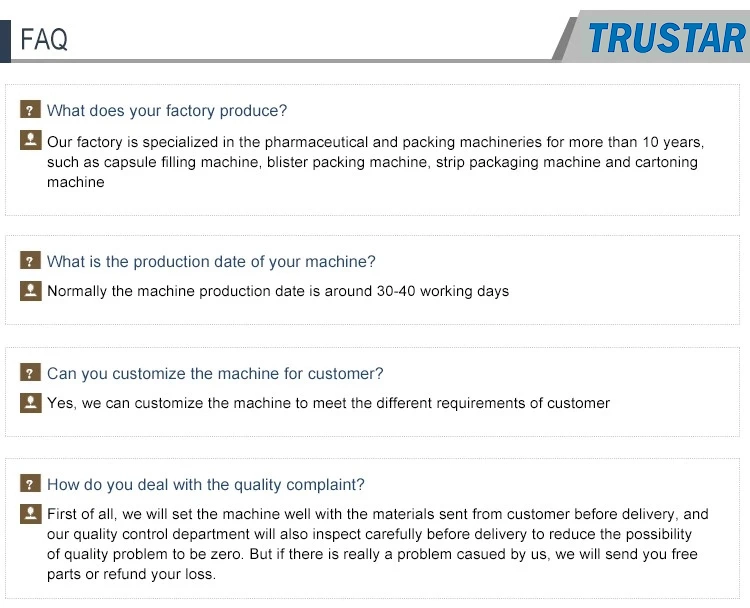

Feature

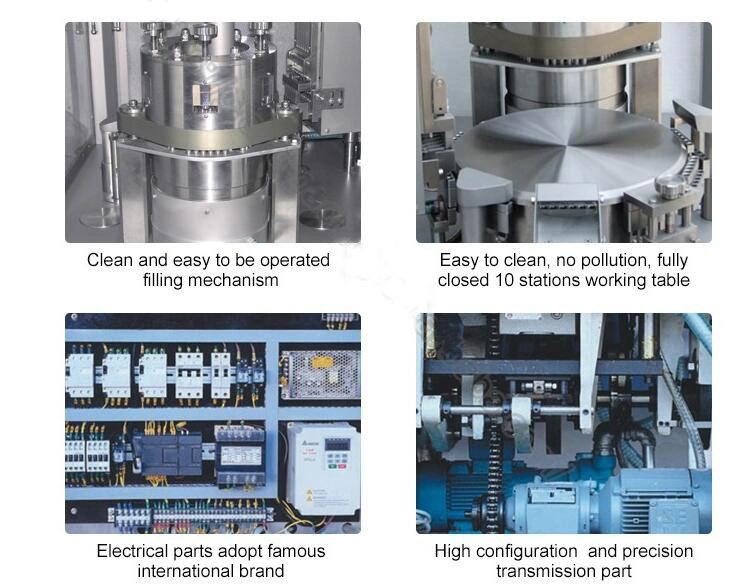

1.Machine design meets GMP requirements and has CE certificate.

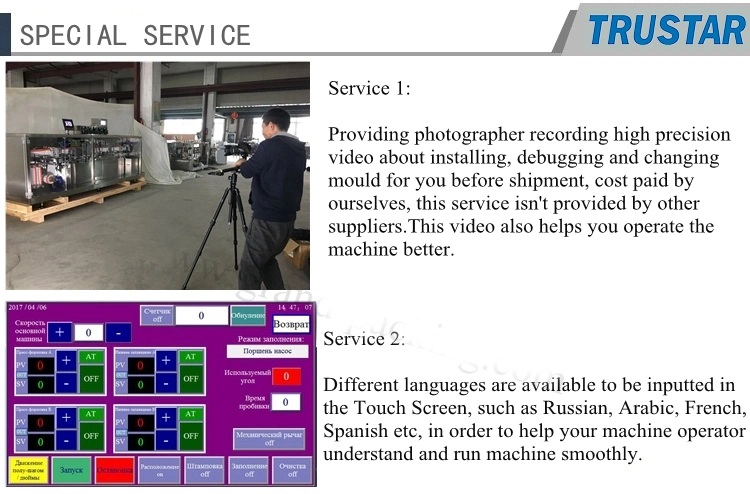

2.Closed turret and dosing station, prevent the powder come into the turret, easy to operate, clean and change over the mould.

3.New turret design, adopt 90 linear bearings from Japan to guarantee the machine precision and use life.

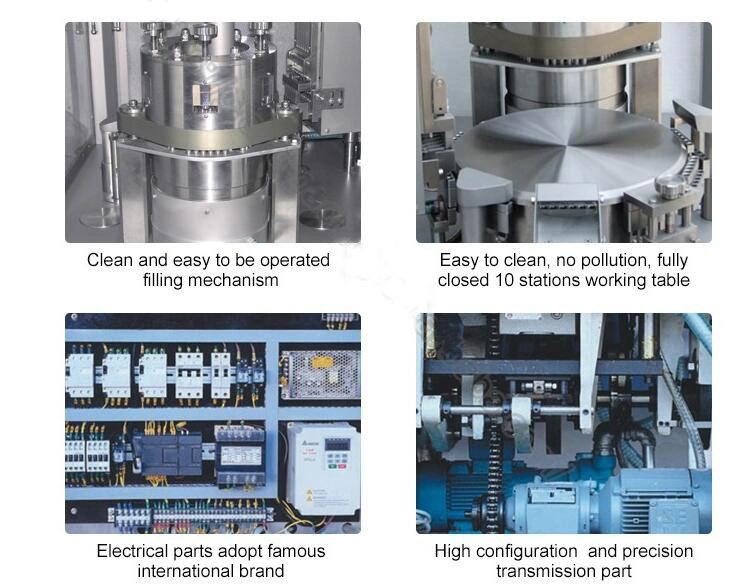

4.Adopt bigger cam & dosing disk design, enhance the stability of the machine and extend the use life of the machine.

5.Equippedwiththe oil pump for supply the lubricate oil to the cam channel,reduce theabrasion and extend the use life of the parts.

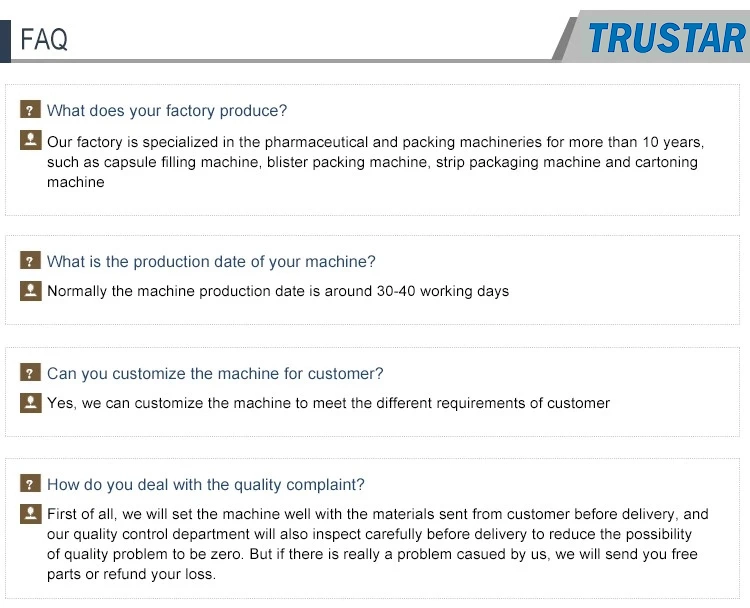

6.Automatic capsule switch, controlled by the touch screen via PLC.

7.Touch screen with user-friendly graphic operator panel.

Parameters

This model is an intermittent motion and hole plate type filling full automatic capsule filling equipment. It adopt optimization design for meeting the characteristics of Chinese medicine and the requirement of GMP, it has the characteristics of compact mechanism, small volume, lower noise, precision filling dosage, multi-function, stably running etc. It can finish the following motion at the same time: capsule feeding, capsule separating, powder filling, capsule rejecting, capsule locking, finished capsule discharge and die hole cleaning etc. It is the most ideal hard capsule filling equipment for pharmaceutical and health food industry.

Feature

1.Machine design meets GMP requirements and has CE certificate.

2.Closed turret and dosing station, prevent the powder come into the turret, easy to operate, clean and change over the mould.

3.New turret design, adopt 90 linear bearings from Japan to guarantee the machine precision and use life.

4.Adopt bigger cam & dosing disk design, enhance the stability of the machine and extend the use life of the machine.

5.Equippedwiththe oil pump for supply the lubricate oil to the cam channel,reduce theabrasion and extend the use life of the parts.

6.Automatic capsule switch, controlled by the touch screen via PLC.

7.Touch screen with user-friendly graphic operator panel.

Parameters

| Machine Model | NJP-800C |

| Max. Output | 48000 Caps/Hour |

| Capsule Size | Suitable for filling capsule size 00#-5# Supro/safety capsule size: A-E (need to exchange the size change parts accordingly) |

| Dosage Type | Powder (Pellet/Tablet for optional) |

| Power Supply | 380V 50Hz 2.3kw (optional) |

| Noise Index | < 75dBA |

| Machine Size/N.W. | 930mm×790mm×1930mm Net Weight:800KG |

| Packing Size/G.W. | 1560mm×1000mm×2150mm Gross Weight:900KG |